sales@ajsw.co.uk | +44 1530 831191

Abrasion Resistant Wear Plates Steel

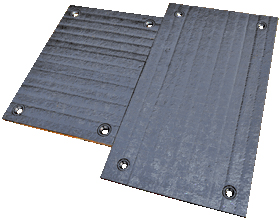

Abrasion Resistant Wear Plates

Steel Carbide

Chrome Carbide Wear Plate

A J Specialist Welding Wear Plate consists of a plate of plain carbon steel which has been clad at our Coalville works with a high chrome carbide deposit. The bonding between the base material and cladding is a true mechanical bond and therefore separation at the interface is virtually impossible.

-

Long life plate

The abrasion resistance of our Abrasion Plate varies with different applications but life increases of 4 to 40 times can be expected as standard.

-

Performance

Our Carbide Wear plates typically perform up to 15 times the life of Manganese Steel. Up to 40 times the life of Mild Steel.

-

Industry Special

Withstands impact and deformations and can be rolled to 10″ radius. Easily welded, or bolted on to chute work etc.

Wear Plates Abrasion Resistant Carbide

We have in house facilities to roll and press A J Specialist Welding Wear Plate to customers requirements. Computer controlled Plasma cutting equipment enables A J Specialist Welding to produce profiles to customers needs in singles or multiples. We can also record details for analysis to anticipate your future requirements.

In more recent years we have also been shipping to mainland Europe. A J Specialist Welding also has close ties with major transport specialists for those customers who do not operate their own vehicles.

Wear Plate Applications

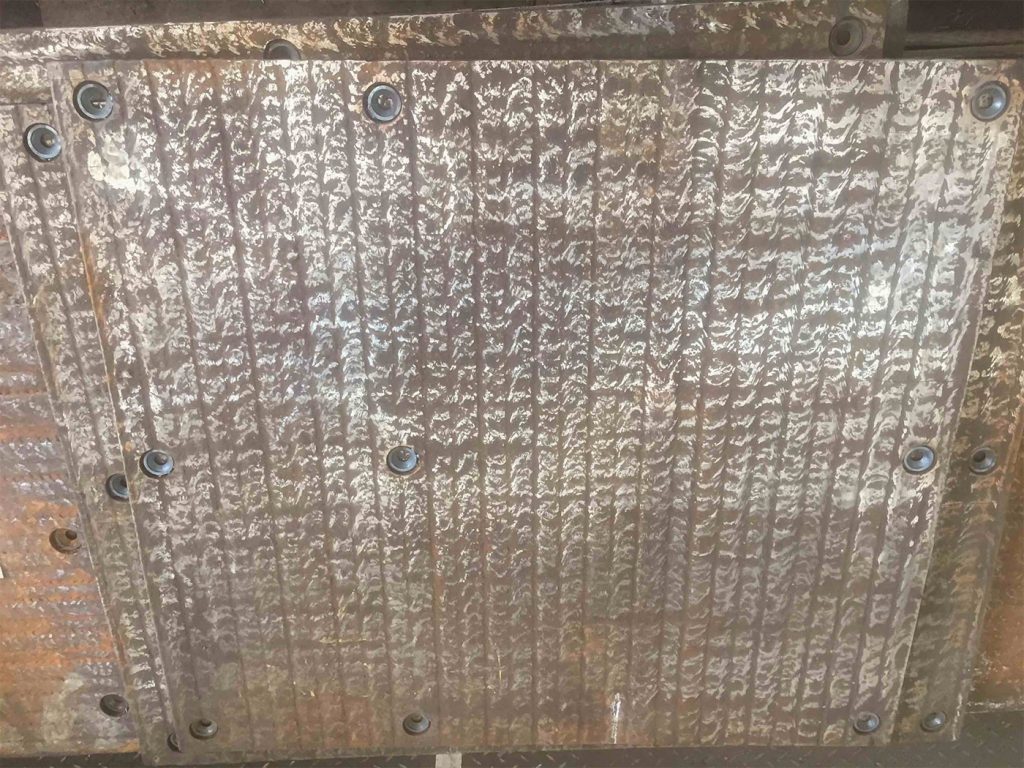

Due to the extreme hardness of the Chrome Carbide there are numerous surface stress relieving cracks on every square foot of the A J Specialist Welding Wear Plate. These are both necessary and desirable.

- Conveyor chutes

- Bunker liners

- Screen liners

- Grizzly bars

- Vibro feeder trays

- Rotor dryer plates

- Mixer, arms, tips

- Fan blades

- Raw mill and classifier liner plate

- Main frame liners

- Screen decks

- Wear plates

- Bucket protection

- Dump truck bodies

- Screen clamping

- Ballast regulator

- Brush box and ploughs

- Wall scrapers

- Concrete mixer liners

Wear Plate Advantages

- Maintenance-free operation.

- Aid to planned maintenance.

- Can save thousands of pounds in maintenance costs and lost production per year (examples available on request).

- Expensive components are clad (e.g. crusher spiders, grizzly bars, screen impact plates, fan impellers, excavator buckets, etc) to prolong component life indefinitely.

- Easily cut using Air Arc, Plasma Arc or Gouging Rods.

- Immediately available in standard strips and plates for general purpose maintenance.

- Supplied to your exact size requirements with holes to suit your existing system.